GHS Labeling

Print Globally Harmonized System (GHS) compliant labels that contain all of the required elements.

Platforms:

EH&S Software Customers

Many of the world’s leading organizations rely on Chemical Safety’s EMS software to help manage their EHS operations. Our customers are both large and small organizations, and they come from a wide variety of industries.

Print GHS Compliant Labels

Print GHS compliant labels and secondary container labels in a multitude of sizes and languages.

Visit our subscriptions page for pricing information.

Product Description

Case Study

GHS Labeling Software

Print GHS Compliant Labels in Multiple Sizes and Languages

Chemical Safety’s cloud-based GHS labeling software allows you to find, display, and print GHS compliant labels in a multitude of sizes and languages. Our GHS labeling software has built-in tables with all of the GHS Hazards and GHS precautionary codes, as well as the signal words and pictograms associated with manufacturer specific chemicals. All of this is available in a cloud-based web application as well as Android and iOS mobile applications which provide wireless access from iPhones, iPads, and Android devices.

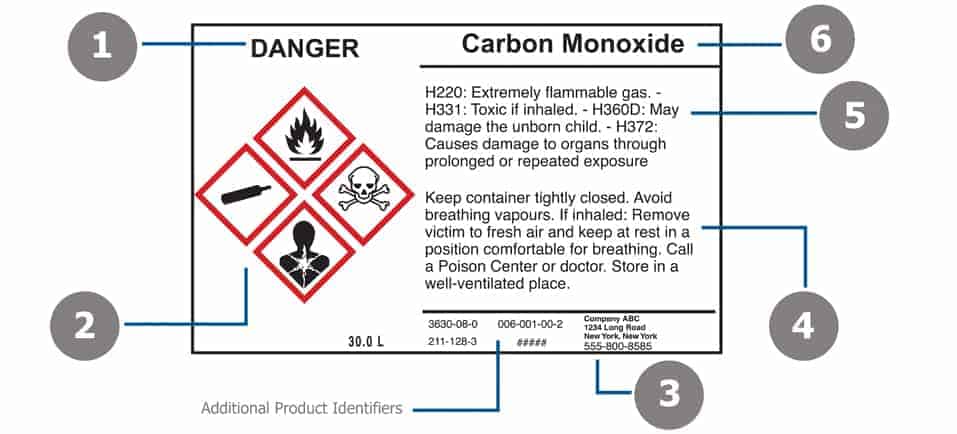

GHS labels require six key pieces of information to be fully compliant:

- Signal Word: used to indicate the relative level of severity of the hazard and alert the reader to a potential hazard on the label.

- Hazard Pictograms: graphic symbols used to communicate specific information about the hazards of a chemical.

- Manufacturer Info: Name, Address and Telephone Number of the chemical manufacturer, importer or other responsible party

- Precautionary Statements: describe recommended measures that should be taken to minimize or prevent adverse effects resulting from exposure to the hazardous chemical or improper storage or handling.

- Hazard Statements: describe the nature of the hazard(s) of a chemical, including, where appropriate, the degree of hazard.

- Product Identifiers: describe how the hazardous chemical is identified.

Integrated with Chemical Inventory Tracking

Chemical Safety’s GHS labeling software is tightly integrated with EMS’s Chemical Inventory Tracking module so it allows for fast and easy printing of inventory container labels with GHS pictograms as well as barcodes. Since inventory items are linked to Safety Data Sheets, extra steps are not required to print GHS compliant labels. The need to store and maintain pre-printed GHS labels is eliminated because on-demand printing is quick and easy.

What Precipitated the Need for GHS Labeling Software?

GHS is an acronym for the Globally Harmonized System of Classification and Labeling of Chemicals, a framework that standardizes the classification and labeling of chemicals worldwide. Its goal is to establish criteria for the classification of health, physical and environmental hazards, and specify what information should be included on hazard labels as well as safety data sheets. For additional information on the GHS labels, visit our Globally Harmonized System (GHS) Cheat Sheet page.

GHS Labeling Case Study

The Challenge

The Environmental, Health and Safety (EHS) department of a global manufacturer of electronic components, with facilities in the US and many other countries was faced with the daunting task of relabeling huge site chemical inventories as required by the newly enacted GHS labeling requirements. Additionally, the company was required to source and update hazard documents (Safety Data Sheets or SDS) for all existing chemicals in the various sites. Chemical inventories were up-to-date through the use of Chemical Safety’s EMS EHS software, which streamlined where chemical information update were necessary.

The Solution

Chemical Safety Software was tasked with implementing a rapid and cost-effective solution to address the needs of the organization. Chemical Safety matched the existing chemical inventories to its vast database of Safety Data Sheets (SDS) and its most up-to-date GHS chemical reference database. Chemicals matched with existing inventories seamlessly, and SDS documents were automatically attached to the chemical container records for each site and location. With the majority of chemicals matched, in a matter of only a few days, the remaining missing data was identified, information was sourced from manufacturers and distributors and the whole project was completed in less than 60 days.

Chemical Safety was subsequently tasked with maintaining and updating this organization’s SDS data, and assuring that the required safety and labeling information is available as required.

This information is not only available on the cloud for the company to access worldwide, but it is also available for all employees of the company on their smartphones and tablets (iOS, Android and Microsoft Surface).

The solution was well received by all parties involved within the company, the EHS department as well as corporate management.

Achieve Environmental Compliance Objectives in Less Time