US companies continue to incur scrutiny from regulatory bodies regarding chemical safety infringements, including failure to submit appropriate environmental compliance reports.

Federal agencies are sharpening their enforcement teeth. They are pushing manufacturers to file electronic risk management plans and safe handling procedures for hazardous and toxic chemicals on site and hazardous waste.

The move to electronic filing is slow, with several recent transgressions.

While the manufacturing sector is broadly racing towards digital transformation, termed Industry 4.0, chemical manufacturers lag. The slower digitization of factory floors and chemical safety reporting operations impacts industry performance and revenues.

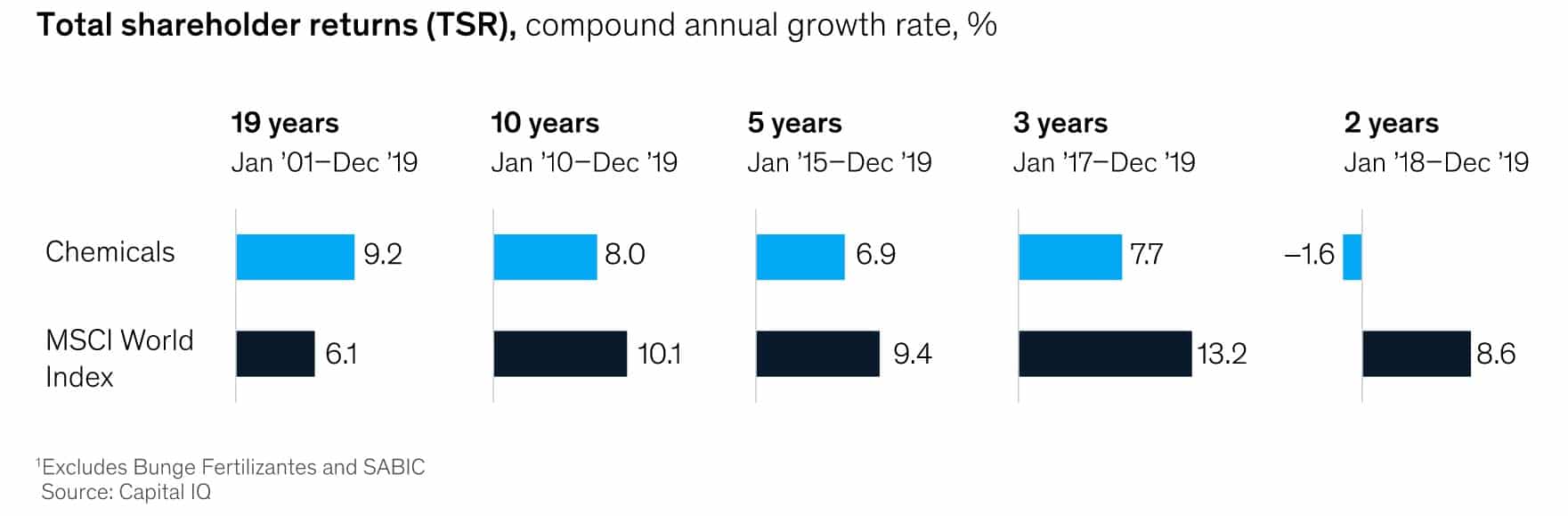

According to McKinsey & Company, the chemicals sector traditionally outperformed the world index, but not in the past few years.

While competition from China is a significant factor, the failure to adopt sustainable operations as defined by the United Nations 17 Sustainable Developmental Goals (SDGs) blunts business agility and competitiveness.

These goals influence global chemical safety regulation, particularly in the United States. Lawmakers are focused on Goal 3, ensuring healthy lives, and Goal 12, sustainable consumption & production.

The UN is calling for substantially reducing deaths and illnesses from hazardous chemicals, air, water, and soil pollution and contamination by 2030.

The focus is on the chemical sector, the world’s third-largest source of industrial greenhouse gases. Chemicals find their way into over 95% of manufactured goods.

Consumers are pushing for more sustainable products while regulators pressure manufacturers to pursue low-carbon operations and reduce hazardous chemicals’ production, use, and risk.

The regulation is becoming more complex, especially as the public debate around “Forever Chemicals” intensifies. A recent report suggests that 80% of US waterways remain contaminated by Per- and Polyfluorinated Substances (PFAS).

Around 12,000 PFAS chemicals appear in everyday household products, including cookware, to resist water, heat, and stains. PFAS may cause cancer, kidney disease, and congenital disabilities.

These findings have compelled the EPA to propose a special one-time reporting rule, requiring chemical producers to record their PFAS contributions in the marketplace. Under the Toxic Substances Control Act (TSCA), the inbound regulation calls for civil and criminal prosecution for non-compliance.

Chemical producers relying heavily on paper and spreadsheet processes to track chemical safety operations face the highest risk of litigation and financial penalties.

The reasons for this are twofold:

- Paper reporting substantially increases filing error rates, impacting genuine attempts to properly track, monitor, update and report chemical use and disposal in their storage facilities. Further, storage needs to be more scalable and take up valuable space. Paper records are harder to secure and difficult to back up. Paper is time-consuming to maintain while slowing down future auditing efforts.

- 90% of spreadsheets contain errors, according to recent studies. Roughly half of the spreadsheet models used operationally in large businesses have material defects. Spreadsheets also lack version control of more sophisticated systems, like databases or Environmental, Health & Safety (EHS) software platforms. They also offer poor data protection and less-than-ideal audit trails.

Both mediums described above are nightmarishly difficult to repurpose towards the evolving requirements of the EPA’s Chemical Data Reporting (CDR) rule falling under TCSA.

Paper and spreadsheets also hamper digital transformation, which ultimately impacts revenue performance, as reflected in the McKinsey report outlined above. Over the next decade, markets will reward companies that pursue sustainability, increasingly dependent on digital transformation. Recent research shows that companies with high ratings for Environmental, social, and governance (ESG) have a lower cost of debt and equity. They also outperform the market over a three-to-five-year timeframe.

The downsides of the paper and spreadsheet approach partially drive recent actions taken by the EPA towards manufacturers who maintain outdated analog approaches to compliance reporting.

Regulatory action

A chemical producer of raw materials for companies operating in low-carbon economies failed to submit nine environmental reports regarding toxic chemicals to the Environmental Protection Agency’s (EPA) TRI database for two consecutive years and was heavily penalized.

An EPA inspection of the facility uncovered several flaws in its design and safety maintenance practices leading to toxic emissions. While cooperative, the EPA ultimately fined the producer $179,596 for non-compliance with the Clean Air Act’s General Duty Clause (CAA GDC) and the Emergency Planning and Community Right-to-Know Act (EPCRA).

The EPA also acted against a chemical warehousing facility for unsafe practices and inadequate compliance reporting, fining the company $109,635. In this case, the company failed to submit complete, timely EPCRA Section 311 and 312 Chemical Inventory reports (Tier II) with federal, state and local emergency planning and response authorities.

“It is unacceptable that chemical warehouses and distribution centers pollute the air our kids breathe and don’t disclose their activities,” said the EPA. “Enforcement actions like these send a strong message to these companies that deal with dangerous chemicals – they must keep the public, and local emergency responders, informed about the chemicals they deal with and ensure they are stored safely to protect the communities they are located in.”

Both cases are part of an initiative to improve safety and compliance at chemical warehouses.

Pressure mounts

Pressure to file timely and accurate environmental reports, including the Federal Tier II and 313 reports, the Waste Biennial Report, The DHS COI report, the pending TSCA report, and several other state and local reports, is mounting daily.

The Occupational Safety & Health Association (OSHA) recently warned that it is expanding its effort to find and punish severe safety and health violators. Companies that expose workers to chemical safety risks after being cited face inclusion in their updated Severe Violator Enforcement Program. Additional citations create burdensome complexity and labor for paper-based or excel-orientated recordkeeping. Transgressors face additional financial penalties and public shaming, which may take years to repair. Public mistrust may affect demand for products, directly impacting revenue and profits.

Ultimately, the goal of both OSHA and EH&S professionals is that workers come home safe at the end of every shift. Plus, both groups desire a Zero Harm Workplace that limits the environmental risk to their local communities, especially concerning the storage, movement, and disposal of hazardous chemicals.

Steering towards sustainability

Reducing data inaccuracies and complex paper and excel operations streamlines EH&S processes and procedures while limiting filing reports late with regulatory bodies. Inaccurate or late resubmissions often contain errors or omissions, raising labor costs and inviting further scrutiny from bodies like the EPA and OSHA. Moving to a singular EH&S cloud platform steers a company towards both goals.

EMS software platforms, like Chemical Safety’s EMS, allow safety teams to transfer location, chemical, and waste data from scattered legacy spreadsheet and paper systems into a single data repository. Managers can monitor data in real-time dashboards, cross-referencing Safety Data Sheets (SDS) and Globally Harmonized Systems (GHS) information. Leadership teams can keep precise and explicit tabs on the use and nature of chemicals in the facility. Other valuable features include the ability to set Inventory warnings and stop limits for each chemical location based on hazard type.

The net result is efficiency, accuracy, fewer errors, and pre-configured electronic reports arriving to regulators on time. Further, streamlined processes through inventory storage, tracking, barcode labels (or RFIDs), and smartphones and tablets, update information easily and accurately.

Digital Transformation Supports Environmental Compliance

Moving to a Software-as-a-Service (SaaS) chemical safety platform also brings an organization closer to digital transformation. Modular, self-optimizing manufacturing facilities, called Factories of the Future, offer superior process safety and worker safety features through automation and data sharing between applications, including Chemical Safety’s Environmental Management Systems (EMS) software.

EMS software platforms, like Chemical Safety’s EMS, allow safety teams to transfer location, chemical, and waste data from scattered legacy spreadsheet and paper systems into a single data repository. Managers can monitor data in real-time dashboards, cross-referencing Safety Data Sheets (SDS) and Globally Harmonized Systems (GHS) information.

Leadership teams can keep precise and explicit tabs on the use and nature of chemicals in the facility. Other valuable features include the ability to set Inventory warnings and stop limits for each of your locations based on hazard type.

Other tools exist to simplify the recording, disposal, and reporting of biohazardous, radioactive, and mixed waste. Chemical Safety’s EMS platform is also e-Manifest ready. Once the EPA authorizes the generation of electronic manifests, you can deploy our cloud software immediately.

Plus, building a library of regulatory reports and permits – all indexed and searchable – gives EMS professionals peace of mind and strong confidence that their organization is compliant. The ability to search for key reports in seconds by keyword or category makes life easier for safety professionals. It also leads to agile operations since cloud recordkeeping scales in tandem with business growth without any need to maintain cumbersome paper records or bulky spreadsheets.

Avoid “Greenwashing” Accusations

There are other essential reasons EH&S professionals should consider adopting an environmental compliance reporting software.

Several companies in the US recently fell afoul of “greenwashing” accusations. They purposely distorted their reporting to make it appear as if they were sustainable and environmentally compliant. Damaged public trust is hard to fix and ultimately impacts a company’s bottom line.

Younger workers are less likely to join a chemical company that is not committed to the United Nation’s 17 SDG goals mentioned earlier. A recent Fast Company survey revealed that 70% of millennials prefer working in a company with a robust sustainability plan. The report confirmed that three-quarters of them would take a salary cut to work for an environmentally responsible firm.

Environmental regulatory reporting software compels leadership teams to adopt sound sustainability practices and produce conservative, reliable reports that adequately outline progress in meeting chemical safety and hazardous waste objectives.

EH&S software also offers the added bonus of exciting and attracting younger generations who enjoy mastering cloud software connected to powerful mobile and tablet functionality.

An EMS Compliance Platform Makes Sense

In summary, implementing a turnkey EH&S cloud-based enterprise platform from Chemical Safety Software helps improve the storage, movement, and safety of chemicals used on the plant floor and throughout the manufacturing lifecycle.

The ability to quickly file electronic reports annually at local, state, and federal levels steer a company safely toward the United Nation’s sustainability goals. It does this by supporting digital transformation efforts and giving the public and regulatory bodies a transparent look into actual chemical operations and their impact on the environment.

The reporting builds strong trust in local communities as they work with chemical companies to reduce the prevalence and impact of Forever Chemicals or PFAS.

Chemical Safety has a 33-year track record in allowing safety professionals to create pre-configured reports. These reports meet regulatory standards, giving leadership teams insights into worker and process safety.

Governments and Fortune 500 companies rely on Chemical Safety’s Environmental Management Systems (EMS) for lifecycle chemical management and environmental compliance reporting.

If your company is committed to pursuing process safety, worker safety, and sustainability under a digital transformation and industry 4.0 framework, please get in touch with us about Chemical Safety offerings at sales@chemicalsafety.com.

We would be glad to outline a strategy and software approach to moving your organization away from outdated paper and excel approaches to environmental compliance reporting.