The earlier version of this article, which I wrote a couple of years ago, has been read and commented on by many people involved in EHS at all levels. This is not surprising to me: we’re all looking for the best possible way to address our industry’s most challenging questions. New technologies and communications tools, including the Web and mobile devices, have created exponential breakthroughs in our industry. This updated article focuses on just that: What new tools and options are available to EHS managers, Lab Safety personnel and others tasked with Chemical Safety and compliance to increase accuracy, reduce costs and improve safety in the workplace?

New global and local regulations and reporting requirements continue to be added at record pace. In this last year alone, the new GHS and SDS standard has caused companies to retool, relabel and retrain at an unprecedented pace. Chemical Safety Software (www.chemicalsafety.com), the company I founded 28 years ago and still manage, receives hundreds of inquiries daily on how to comply with the upcoming GHS deadline for employers. This is only an example, an important example, of the many compliance requirements that operations personnel in almost every industry have to deal with.

I have a new first rule when it comes to best practices: DO IT NOW! The technology and tools available today, with cloud-based EHS software services and mobile solutions on smartphones and tablets, coupled with deployment and implementation costs that are a fraction of what they were even a year or two ago, are indisputable reasons why you should progress to new, more reliant technology tools. OUT WITH THE OLD; IN WITH THE NEW!

I am a big advocate for cloud-based, Software-as-a-Service (SaaS) EHS software solutions. Many of the world’s most innovative companies are transitioning from legacy enterprise systems to pay-as-you-go solutions for chemical inventory management, waste disposal, environmental regulatory compliance, workplace safety and lab safety. Available online 24/7 and accompanied by easy-to-use EHS mobile applications for chemical inventory tracking, hazardous Waste management, GHS labeling & SDS, and safety inspections. These EHS mobile apps can be used anywhere, anytime, and they provide measurable improvements in accuracy, efficiency and cost-savings.

Best practices for EHS chemical management need to capitalize on technology breakthroughs that have eliminated time-consuming and cost-prohibitive EHS software implementations. Cloud SaaS computing provides meaningful alternatives to overcome all these challenges and more. For EHS, adapting to the cloud will simplify the complex, yet enhance efficiency, accuracy, and safety.

Here are some key points:

- Flexibility and Scalability: With Cloud computing, companies can scale up or down rapidly, cost-effectively and with very little risk.

- Speed of Implementation: With cloud computing EHS software implementation time can be virtually instantaneous.

- Capital Expense Avoidance: Signing up on a monthly plan is a single-click action that falls far below the radar of corporate spending limits.

- I.T. Independence: Eliminating internal IT resources for EHS software by using cloud-services on servers that are up 247, are updated regularly and are backed up daily provides enormous savings to the company.

- Technology updates: Cloud vendors are solely responsible for updating the software with new rules and regulations as well as technology upgrades.

- Security: Cloud companies are committed to investing in data security. Cloud applications operate in secure data centers with layers of information protection and security tools that smaller companies can now benefit from through economies of scale.

- Disaster Recovery: Since all business logic and data is stored in the cloud, cloud companies are diligent in managing, backing up and mirroring their installations, offering unprecedented uptime and rapid data recovery and disaster avoidance.

- Information Sharing and Collaboration: In the cloud, non-confidential data can be accessed in a central location with round the clock availability by everyone. New information like the newly enacted GHS labeling and Safety Data Sheet mandate can now be updated by many and available to access and use by many more, anywhere, at any time!

- Mobility: With no physical tie to the system, employees are empowered to work from anywhere and everywhere on a variety of devices. iPhones and iPads, Android smart phones and tablets all have built-in tools like the camera, for example, that can be used to read barcodes and update chemical information instantly and accurately. Cloud-based SaaS software can create virtual offices at home, on holiday and even on the daily commute. In today’s rapid development world, cloud applications can be accessed on mobile devices virtually everywhere.

- Application Support: EHS application users need expedient and effective help which traditionally they have never gotten either from the software vendor or from their own IT staff. Cloud-based EHS installations address support issues better than ever before. The Cloud vendor is the only responsible entity that must provide user support and they are able to do so rapidly and efficiently since they have control of the installation and every aspect of it.

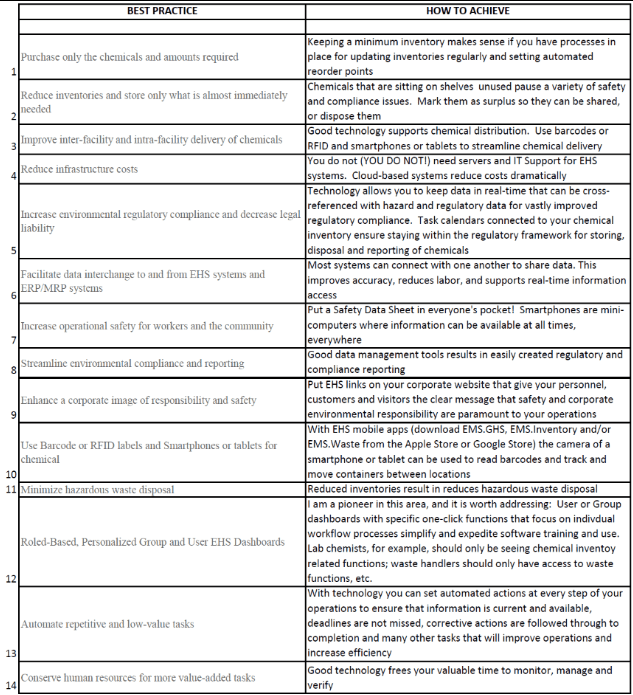

I have copied below the key elements for Best Practices from my last article, and have added, right next to them, tips on HOW to achieve them!

Best Practices for EHS Chemical Management:

Environmental Health and Safety is still viewed as a necessary evil, but best practices will reduce this impression, especially when results are achieved with reduced resources and cost. The goals should be that EHS is viewed as a critical part of the business process and integrating it with other activities can raise efficiency of chemical management and provide a significant advantage in terms of cost savings, safety, risk management and competition. Implementing Best Practices helps this integration of EH&S with the organization’s processes, and supports the strategic or business goals of saving money and growing the business. On the day-to-day level, these operations affect the tactical or management goals of increased safety and decreased legal and regulatory risk. Reviewing the impact, cost savings and benefits become clear.

The Bottom Line

The costs of managing chemicals are far greater than the cost of buying a chemical, but the life-cycle management of chemicals can be optimized to reduce these costs. By adopting best practices, the chemical management process is integrated into the business process, becoming a strategic advantage to the organization, raising efficiency on a number of fronts, decreasing legal liability and risk and improving plant/laboratory safety, as well as offering bottom line cost savings. Improved information management systems are becoming more functional and less costly, making these process improvements possible. Such systems are still an investment, and costs of re-engineering operations and changing current processes must be considered, but the savings of a concerted, focused effort to improve EHS chemical management are significant, and the ROI quickly justifies the costs.

I welcome your comments. For more information and an evaluation of your organization’s operational needs and requirements, please contact Tony Diamantidis, Executive Vice-President, SFS Chemical Safety, Inc. tonyd@chemicalsafety.com, (510) 594-2020, https://www.linkedin.com/in/tonydiamantidis